types of impact tests|impact test for plastic material : makers Types of Plastics Impact Testers. The two most basic and well known impact pendulum testers for plastic materials are the Izod and Charpy. These plastic impact test methods measure the energy absorbed by the specimen caused . Yes! You can play the game for free in your browser without having to download the game. Play Subway Surfers using your keyboard and mouse. . Ver mais

{plog:ftitle_list}

Resultado da Contos eróticos, histórias e relatos enviados pelos melhores autores da língua portuguesa. Um dos acervos mais tradicionais, desde o ano 2000 .

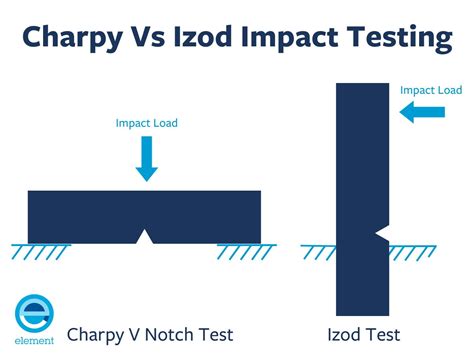

An impact test is a technique used to determine a material’s ability to resist deformation when subjected to a sudden shock or impulse load. There are several different types of impact tests, but all entail striking a prepared .Types of Plastics Impact Testers. The two most basic and well known impact pendulum testers for plastic materials are the Izod and Charpy. These plastic impact test methods measure the energy absorbed by the specimen caused .The most common configuration for pendulum impact test are Izod and Charpy ones. The scope of these impact test is to measure the answer of a standard test specimen to the pendulum . The purpose of this article is to provide an overview of the basics of impact testing. Our discussion will cover the different types of impact testing, the necessary equipment, and the valuable data these tests provide.

There are basically two types of impact tests: pendulum and drop weight. Izod, Charpy, and tensile impact are the most common of the pendulum type tests.

There are two main forms of impact test, the Izod and the Charpy test. Both involve striking a standard specimen with a controlled weight pendulum travelling at a set speed. The amount of energy absorbed in fracturing the test piece is . Charpy and Izod tests (also known as “notch impact tests”, “notched impact tests” or “V-notch tests”) are two of the most commonly used impact testing methods. Charpy and Izod Automatic Impact Tests. Both .

skinfold thickness measurements

In automotive and other safety-critical industries, impact testing is an important measure of a material’s failure properties. Properly testing both raw materials and molded components for their strength and durability can help .

Impact test specimen types include notch configurations such as V-notch, U-notch, and keyhole notch. Impact testing most commonly consists of Charpy and Izod specimen configurations. The Izod impact test differs from Charpy impact test in the way that the notch is positioned facing the striker. Thus in the Charpy test, the test piece is held .An impact test determines a material’s resistance to an impact event. It measures the amount of energy the material absorbs when it is hit by a high-rate load. The most common impact test methods are Charpy . Other types of impact tests, including Tensile Impact, Dynstat, and Pipes can be carried out using a pendulum1.There are two traditional standards for measuring impact resistance: the Charpy pendulum impact test (ISO 179/ASTM D6110) and the Izod test (ISO 180/ASTM D256). These two test methods are used to certify the impact resistance of a .

Parametric tests usually have stricter requirements than nonparametric tests, and are able to make stronger inferences from the data. They can only be conducted with data that adheres to the common assumptions of statistical tests. The most common types of parametric test include regression tests, comparison tests, and correlation tests.

Tensile impact test procedures. The tensile impact strength test was originally developed to overcome the deficiencies of flexural (both Izod and Charpy) impact test. All the test variables that have a high effect on the results, such as notch sensitivity, toss factor and specimen thickness, are eliminated in the tensile impact test.There are two traditional standards for measuring impact resistance: the Charpy pendulum impact test (ISO 179/ASTM D6110) and the Izod test (ISO 180/ASTM D256). These two test methods are used to certify the impact resistance of a variety of materials, including metals as well as plastics, resins, and composites.Material impact toughness can be measured by various types of test such as the Charpy V-notch impact test, Izod test or K IC test. The most commonly used test is the Charpy impact test (see Fig. 6.9), which gives an indication of the toughness of a material at a specified temperature.It is not a particularly accurate test but can give a general indication of the ability .Generally, the impact testing methods can be divided into two separate types: low velocity impact by a large mass (drop-weight tests or pendulum) and high velocity impact by a small mass (runway debris or small arms fire) [25]. The more common methods are low velocity impact by a large mass.

Impact testing serves to assess a material’s impact toughness, representing its resistance to impact forces. The ability to quantify the impact property is a great advantage in product liability and safety. This involves three main tests: the tensile impact test, the Charpy V-notch test, and the Izod impact test.Charpy Impact Testing. Izod Impact Testing. Tested Materials . Plastics. Plastics. Types of Notches (0.25mm) Preferred. V-notch . V-notch . Specimen Position. Horizontally, Notch facing away from the pendulum. Vertically, Notch facing towards the pendulum. Point of Impact. Middle (center) of the sample. Upper Tip of the sample. Common Specimen .

The most popular impact tests are the Charpy test and the Izod test. These two tests determine essentially the same material characteristics, but differ in the orientation of the test sample, which causes the sample to be stressed in different directions and involves a known weight released from a known height colliding with the sample in its test structure.Charpy Impact Test: In this method, a test specimen is held at one end and struck on the opposite end with a pendulum hammer. The amount of energy absorbed by the specimen during fracture is measured. Izod Impact Test: This test method is similar to the Charpy impact test, but the specimen is held vertically, and the hammer strikes the specimen on the same side as . Impact tests are used to measure the impact toughness of a material. These tests are important for understanding how materials will behave in situations like car accidents (crashworthiness) or other high-impact events. Impact testing can provide valuable information about a material’s ability of the material to absorb energy during impacts or . The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is abruptly subjected to bending stress. The specimen is usually 55 mm long and has a square cross-section with an edge length of 10 mm.

Each of these test methods, or test types, will reveal different behaviors and characteristics; we can help you pinpoint the test type that you need. The links below will bring you to a summary page of the given test that can help shed some light on which test type you need for your application. You will find in formation on corresponding . Impact test specimen types include notch configurations such as V-Notch, U-Notch, Key-Hole Notch, as well as Un-notched and ISO (DIN) V-Notch, with capabilities of impact testing subsize specimens down to ¼ size. . Puncture Test Method: Accurate Break Type Calculations . Some impact tests like the puncture test method (specified by the ASTM D3763 / ISO 6603 standards) require more sophisticated calculations. This multiaxial .

thickness measuring devices

Understanding the critical importance of Charpy Impact Testing sets the stage for delving into its step-by-step procedure and intricacies – an insightful journey that demystifies this essential method for assessing material toughness. Step-by-step Procedure of a Charpy Impact Test. Performing a Charpy impact test involves several important steps.

The Two Types of Charpy Impact Test Results 1. Quantitative Results. Quantitative data is data based on numerical values. In the Charpy impact test, this quantitative data is normally the energy absorbed during the fracture of the sample. The DBTT (Ductile-to-Brittle Transition Temperature) can also be estimated by testing the multiple samples .

6 Types of Mechanical Tests. The most common types of mechanical tests include Tensile test, Compression test, Hardness test, Impact test, Fatigue test, and Torsion test. Tensile testing. Tensile testing is a type of mechanical test used to measure the properties of a material when subjected to tensile forces. The test involves applying a . Charpy Impact Test. One of the most common types of impact testing is the Charpy impact test. This method involves striking a notched specimen with a pendulum hammer and measuring the amount of energy absorbed by the material before it fractures. The results are typically reported as energy absorbed in joules (J) or foot-pounds (ft-lbs).ImPACT is a computerized concussion assessment tool for ages 12-59. By comparing baseline and post-injury ImPACT test results, you can make confident treatment decisions.

tool for measuring glass thickness

Many of these types of testing can be done manually — or they can be automated. 1. Accessibility Testing . . Through regression testing, businesses can confirm that updates and changes to code do not have a negative impact on software features. Today, regression testing is essential as applications and software are developed almost daily. . ASTM E2248 – 18: Standard Test Method for Impact Testing of Miniaturized Charpy V-notch Specimens.; Ductile to brittle transition in impact testing. Carbon steel and low alloy steel are characterized by the fact that the fracture behavior changes as the temperature drops and the fracture type changes from ductility to brittleness. There are many different types of tests and selection procedures, including cognitive tests, personality tests, medical examinations, credit checks, and criminal background checks. . The test had a significant adverse impact on women – prior to the use of the test, 46% of hires were women; after use of the test, only 15% of hires were women

Impact testing is classified according to how a material resists impact. The following are the different types of impact test machines: Charpy Impact Test: The Chapy impact test is a widely used method to determine the toughness of a material. In this test, a pendulum is swung by a weight on the top of a test sample to create an impact.

There are two traditional standards for measuring impact resistance: the Charpy pendulum impact test (ISO 179/ASTM D6110) and the Izod test (ISO 180/ASTM D256). These two test methods are used to certify the impact resistance of a variety of materials, including metals as well as plastics, resins, and composites.

izod impact test vs charpy

WEB14 de dez. de 2022 · Betclic App Download. A Betclic App está disponível para os dois sistemas operativos: iOS e Android. Vê agora como instalar a aplicação do momento .

types of impact tests|impact test for plastic material